Spring materials

Contents |

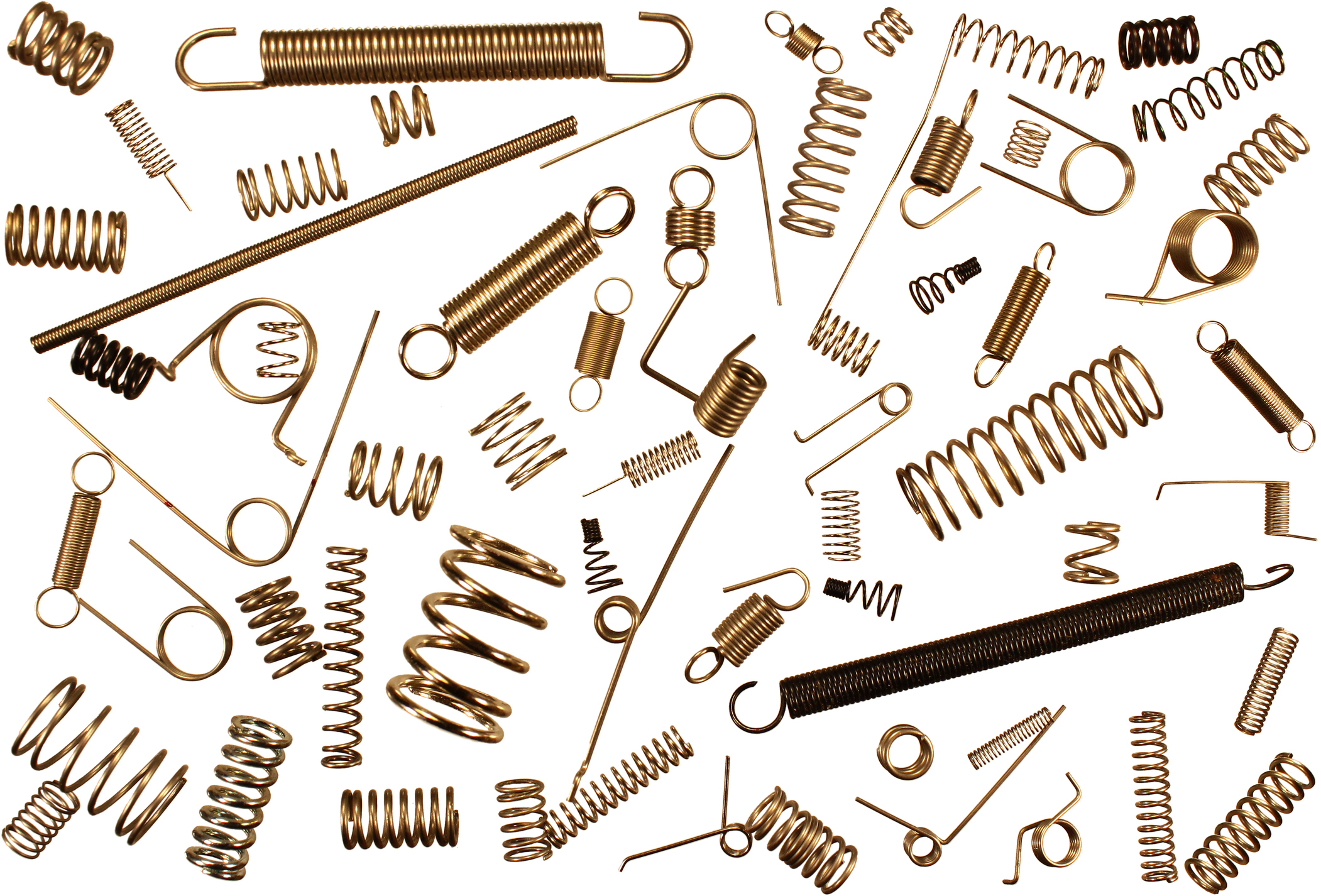

[edit] Introduction

Springs are used in a huge range of different applications and are created in a variety of shapes, sizes and materials in order to fulfil different requirements. These different spring materials are used based on the requirements of the spring and present their own advantages and disadvantages.

While some materials boast a high resistance to corrosion, others may present a strength advantage. As technology advances, manufacturers and engineers are looking to create materials that are capable of being used in applications that may never have been necessary before, such as aerospace.

[edit] Stainless steel

Stainless steel is a commonly used alloy which is used in a huge range of applications. Stainless steels have a minimum of 10.5% chromium and other alloying elements are added to enhance the structure. This material is known for its excellent corrosion resistance so it is often used in architectural applications.

As a spring material, stainless steels are a popular choice due to their corrosion and heat resistance. These qualities mean that the alloy can maintain its integrity and remain strong in a number of applications where other materials may fail or degrade.

[edit] Alloy steels

Alloy steels are steels which have one or more alloying elements added to them in order to improve their properties. They may feature alloys such as manganese, silicon, nickel, titanium, copper, chromium or aluminium, to name a few.

Alloy steels often have improved strength, toughness, corrosion resistance, hardenability and hot hardness. This means that they are often used in applications that require a great deal of hardiness, such as in the aerospace and military fields.

[edit] Titanium alloys

Titanium alloys are made up of a mixture of titanium and other chemical elements. They are divided into grades which differentiate their properties and benefits such as formability and ductility.

This material tends to be lightweight even though other properties include extreme corrosion and heat resistance. Due to the hardwearing qualities of this material, it is often used in applications including aerospace, medical and automotive.

[edit] Copper alloys

Copper alloys are primarily composed of copper but have other metals added to create varying alloys with different properties and benefits. Bronze is the best-known copper alloy, and brass is another example.

These alloys have a high resistance to corrosion. Aluminium bronzes are particularly high in strength and corrosion resistance and can often be found in marine applications.

[edit] Super-alloys

Super-alloys benefit from the following characteristics:

- Excellent mechanical strength.

- Resistance to thermal creep deformation.

- Good surface stability.

- Resistance to corrosion or oxidation.

Due to these qualities, super-alloys are most commonly used in particularly high-stress applications, such as in the aerospace and marine sectors.

[edit] Related articles on Designing Buildings

- Bronze.

- Compression springs.

- E-Spring.

- Extension Springs.

- Flat springs.

- Key qualities of springs.

- Tension springs v torsion springs.

- The Importance of Gas Springs.

- Using springs in construction to prevent disaster.

--European Springs and Pressings Ltd 13:59, 16 Aug 2017 (BST)

Featured articles and news

ECA progress on Welsh Recharging Electrical Skills Charter

Working hard to make progress on the ‘asks’ of the Recharging Electrical Skills Charter at the Senedd in Wales.

A brief history from 1890s to 2020s.

CIOB and CORBON combine forces

To elevate professional standards in Nigeria’s construction industry.

Amendment to the GB Energy Bill welcomed by ECA

Move prevents nationally-owned energy company from investing in solar panels produced by modern slavery.

Gregor Harvie argues that AI is state-sanctioned theft of IP.

Heat pumps, vehicle chargers and heating appliances must be sold with smart functionality.

Experimental AI housing target help for councils

Experimental AI could help councils meet housing targets by digitising records.

New-style degrees set for reformed ARB accreditation

Following the ARB Tomorrow's Architects competency outcomes for Architects.

BSRIA Occupant Wellbeing survey BOW

Occupant satisfaction and wellbeing tool inc. physical environment, indoor facilities, functionality and accessibility.

Preserving, waterproofing and decorating buildings.

Many resources for visitors aswell as new features for members.

Using technology to empower communities

The Community data platform; capturing the DNA of a place and fostering participation, for better design.

Heat pump and wind turbine sound calculations for PDRs

MCS publish updated sound calculation standards for permitted development installations.

Homes England creates largest housing-led site in the North

Successful, 34 hectare land acquisition with the residential allocation now completed.

Scottish apprenticeship training proposals

General support although better accountability and transparency is sought.

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.